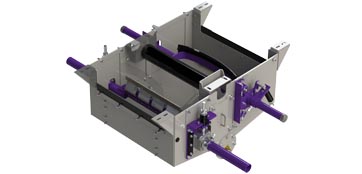

Belt Cleaner Accessories

Browse our line of Belt Cleaner Accessories, which enhance productivity and make installation and maintenance of Flexco cleaners even easier.

- Spray Poles

- Stabilizing Rollers

- Wash Box

- Inspection Doors

- Optional Mounting Kits

- Spring Tensioner Accessories

Browse Belt Cleaner Accessories

Resources

MINELINE®

When standard products just won't do.

Flexco Mineline® products are designed and engineered to work in some of the toughest applications in the world that test the strength and durability of your conveyor system. Products carrying the Mineline® name are proven to work — even where other products have failed.