Major Poultry Processor Reduces Product Waste and Boosts Yield Efficiency with FGP-C Primary Cleaner

Industry

Food Processing – Proteins

Application

Belt cleaning

Product

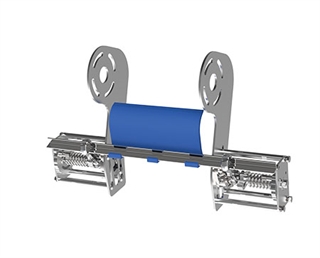

FGP-C Food Grade Primary Cleaner for Cleated Modular Belts

Objective

• Reduce material loss

• Minimise resource usage

• Limit labor costs

Conveyor Detail

• Plastic modular belt with flights/cleats

• Belt width: 18-inch wide

• 3-inch cleats

• 20-inch centers

• Belt speed: 5-6m/sec

Problem:

A leading poultry processing facility in the Midwest United States was experiencing significant product loss on its debone and trim lines. During processing, their belts convey chicken frames on the way to a process called Mechanically Separated Chicken (MSC). One particular conveyor was generating excessive waste, leading to inefficiencies in both yield and labor. The flighted belt’s catch bin had to be emptied 15-16 times per day, each containing 35-40 pounds of lost product, an issue that not only impacted profitability but also escalated sanitation time and labor costs. Recognizing the financial and operational strain, the plant’s operations manager sought a solution to improve material recovery and streamline cleanup efforts.

A leading poultry processing facility in the Midwest United States was experiencing significant product loss on its debone and trim lines. During processing, their belts convey chicken frames on the way to a process called Mechanically Separated Chicken (MSC). One particular conveyor was generating excessive waste, leading to inefficiencies in both yield and labor. The flighted belt’s catch bin had to be emptied 15-16 times per day, each containing 35-40 pounds of lost product, an issue that not only impacted profitability but also escalated sanitation time and labor costs. Recognizing the financial and operational strain, the plant’s operations manager sought a solution to improve material recovery and streamline cleanup efforts.

Solution:

After reaching out to a trusted belt conveyor solutions provider, the facility conducted an on-site waste walk assessment with a Flexco territory manager. During the evaluation, the team pinpointed key problem areas and identified an opportunity to trial the FGP-C Food Grade Primary Cleaner on their cleated belt system. Designed to provide superior cleaning performance without compromising food safety, the FGP-C was a strong candidate for the application. Following installation, the plant monitored its effectiveness, tracking reductions in waste and improvements in operational efficiency.

Result:

The cleaner’s precision scraping mechanism immediately removed excess material from the belt, drastically cutting down on product loss and reducing the frequency of required catch bin disposals, one of the operations manager’s biggest concerns. The food-safe construction of the FGP-C also ensured compliance with sanitation regulations, a critical factor given the sensitive nature of poultry processing. As a result, the facility saw an 85% improvement in yield efficiency, translating to an estimated $140,000 in additional cost savings. With a payback period of just 28 days, the cleaner quickly proved its value and then some. Beyond yield gains, the facility also realized substantial labor and resource savings, including shorter sanitation cycles that freed up workers for other tasks, lower water usage that cut costs and supported sustainability goals, and a significant reduction in product waste, minimizing overall expenses and improving plant efficiency.

____________________________________________________________________________________

What Does Flexco Accumulating Value Mean?

When you see the Flexco Accumulating Value (FAV) icon, you can expect a Real-Life Result that represents the measurable, repeatable value added to an operation through its investment in a Flexco solution.

FAV results document the ongoing dollar value realized with implementation of Flexco products or services and details how that value helps operations achieve and maximize their productivity, efficiency, throughput, output, and uptime.

Product Group

- Belt Cleaning Systems

Product Line

- FGP-C Food Grade Primary Cleaner for Cleated Belts

Industry

- Food Processing