FLEXCO NEWS

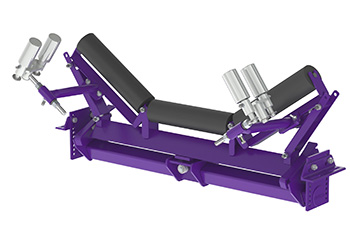

Flexco Increases Mounting Options with PT Max™ Adjustable Belt Trainer

Flexco recently announced the addition of the PT Max™ Adjustable Belt Trainer to its line of Belt Conveyor Products. The adjustable version of the popular PT Max retains the same features of the PT Max - the patented pivot tilt design and stainless steel pivot bearing – but now has more flexible mounting options and is supplied with idlers included.

Flexco recently announced the addition of the PT Max™ Adjustable Belt Trainer to its line of Belt Conveyor Products. The adjustable version of the popular PT Max retains the same features of the PT Max - the patented pivot tilt design and stainless steel pivot bearing – but now has more flexible mounting options and is supplied with idlers included.

The PT Max Adjustable no longer requires data sheets, as each trainer has horizontal and vertical mounting adjustment, as well as trough angle adjustment on the topside that allows it to fit nearly any structure.

The heavy-duty, mine-tough PT Max Adjustable Belt Trainer is designed to work in multiple applications – top side or return side belts, wet or dry conditions, and mistracking to one or both sides. With pivot/tilt action, the PT Max applies greater belt tracking discipline than pivot-only devices, correcting even the most stubborn tracking problems on high-volume, high-tension belts.

When responding to belt mistracking, the PT Max turns away from the direction of drift. Tilting results automatically from pivoting, driven by outer rollers on both ends of the pivoting carriage.

The resulting tilt increases belt tension along the drift-out side, causing the belt to center itself naturally, while keeping the load distributed across the training carriage and avoiding the need for concentrated steering forces along the belt edge.

The pivot/tilt action is initiated by two pairs of sensor rollers installed alongside both belt edges. These rollers are positioned upstream from the trainer to eliminate the need for reversing, multi-jointed downstream linkages that involve more moving parts with more potential points of seizure. They also feature extra-long sensor arms to avoid any potential for belt binding or pinching as corrective training takes place. This allows for greater sensitivity to minor amounts of belt drift and is user-adjustable from beside the conveyor, utilizing standard wrenches to change sensor-roller proximity to the belt. Using dual rollers gives the PT Max twice the amount of edge-contact surface compared to single-roller sensors, which minimizes belt-edge wear, as well as sensor roller wear.

The stainless steel pivot bearing – where many conventional pivoting trainer designs accumulate carryback materials and ultimately seize up – requires no lubrication and is housed in a machined recess that protects it from any falling carryback. The robust construction of the PT Max uses corrosion-resistant materials for long life and minimal maintenance.

Models are available for belt widths from 36" to 84" (900-2100 mm).

For more information on the PT Max Adjustable Belt Trainer, or any other Flexco solutions, log on to www.flexco.com.

Published Date

August 22, 2018Product Group

- Belt Positioners, Trackers, and Trainers