Partner with the EXPERTS in Belt Conveyor Solutions

Please wait while we gather your results.

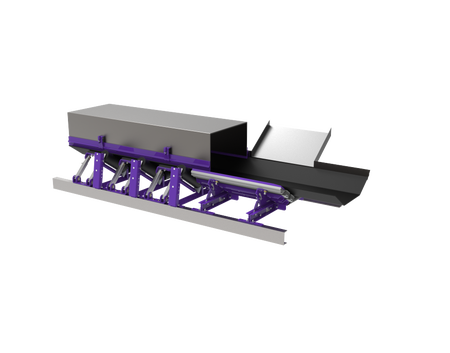

Flexco Introduces the Adjustable Bump Out

By utilizing a user-adjustable angling system, the Adjustable Bump Out guides luggage back to the intended product flow, preventing jams and maintaining optimal spacing and speed throughout belt conveyor processes.

LEARN MORE

Flexco Introduces the Novitool® Pun M™ 1500 Mobile Finger Punch

This Pun M catalog addition features a wider punching surface area that allows operators to punch fingers into their polyurethane and PVC conveyor belts, up to 60” (1500 mm) in width. Like the other Pun M widths, the punch frame ends are open so that continuous punching of belts beyond the punchboard width is possible.

LEARN MORE

Flexco Introduces the Novitool® Aero® with Intellisplice™ Technology

On top of tangible user interface upgrades, the Novitool Aero with IntelliSplice Technology will feature Wi-Fi and BLE connectivity capabilities. With Aero Recipe Management, operators can access their entire recipe library via the Aero Mobile App, seamlessly creating, editing, and deleting recipes and syncing back to the Aero press.

CLICK HERE

Please wait while we gather your results.

How Ignoring Conveyor Belt Sag Hurts Profit Margins in Mining Operations

February 19, 2025

Belt sag might seem like a minor issue, but in heavy-duty mining operations, its impact can be massive. From increased dust and material spillage to costly belt and conveyor system damage, leaving sag unaddressed eats into profit margins and compromises worker safety. Discover why proactive solutions like the Flexco Belt Support Bar are the key to reducing downtime, enhancing productivity, and safeguarding your operation’s bottom line.

Read More...

Heavy-Duty Spotlight: Important Questions for Steel Cord Belt Systems

February 04, 2025

Steel cord conveyor belts are a critical component in the heavy-duty mining industry, offering unparalleled strength and performance. But when these belts experience damage, the resulting downtime can be costly and disruptive. Our latest blog explores the key benefits of steel cord belts, the challenges of splicing them, and the essential questions every maintenance team should ask to prepare for unexpected downtime.

Read More...

Please wait while we gather your results.

Belt Support Bars Eliminate Costly Spillage for Southeast Nevada Mining Operation

A Southeast Nevada aggregate mining operation was losing valuable material and spending excessive time on cleanup due to persistent belt spillage issues. Their vacuum truck operator was working 8-hour shifts every other day just to clean up scattered debris, creating safety hazards and draining profits. After consulting with their Flexco territory manager, they discovered the root cause and implemented a simple solution. Read how Belt Support Bars transformed their most problematic spillage zone into a clean, efficient operation, delivering immediate results and cost savings of nearly $23,000 annually!

Leading Poultry Processor Cuts Labor Costs and Maximizes Product Recovery with FGP-C

A poultry processing facility in the southern U.S. was spending extra labor hours every day recovering product from the catch pans beneath their trim collection conveyor. After recognizing the rising costs, they reached out to their local Flexco representative for help. Read how the FGP-C Food Grade Primary Cleaner helped them reduce manual cleanup and improve product recovery, resulting in potential savings of over $58,000 per year!